Differences Between Heat Transfer Paper and Regular Paper

Heat transfer paper and regular paper may appear similar at first glance, but they have fundamental differences in composition, purpose, and functionality. These differences significantly impact their applications and performance in printing tasks.

## Composition and Structure

### Heat Transfer Paper

– **Specialized Coating**: Features a unique heat-activated adhesive layer or sublimation coating

– **Multi-layered**: Typically consists of a base paper with additional functional layers

– **Heat-Responsive**: Contains components that react to heat application

– **Release Layer**: Includes a release coating that allows the design to separate from the paper

– **Thickness**: Generally thicker and more substantial than regular paper

### Regular Paper

– **Simple Structure**: Made primarily of wood pulp fibers

– **Single-layered**: Lacks specialized functional coatings

– **No Heat Reactivity**: Does not change properties when heated

– **Consistent Composition**: Uniform throughout the sheet

– **Various Weights**: Available in different thicknesses for various purposes

## Functionality

### Heat Transfer Paper

– **Image Transfer**: Specifically designed to transfer designs onto other surfaces

– **Heat Activation**: Requires heat application (typically 350-400°F/175-205°C) to function

– **Pressure Responsive**: Works in conjunction with pressure from a heat press

– **Permanent Application**: Creates lasting designs on the target substrate

– **Specialized Ink Compatibility**: Often requires specific types of ink (sublimation ink, pigment ink)

### Regular Paper

– **Direct Use**: Intended for direct viewing, writing, or printing without transfer

– **No Transfer Capability**: Cannot effectively transfer images to other materials

– **Heat Sensitivity**: May burn, yellow, or degrade when exposed to high heat

– **Standard Ink Absorption**: Works with standard printer inks without special requirements

## Applications

### Heat Transfer Paper

– **Textile Decoration**: T-shirts, hoodies, caps, and other fabric items

– **Product Customization**: Mugs, mousepads, phone cases, and promotional items

– **Crafting**: DIY projects requiring image transfer

– **Small Business Production**: Custom merchandise creation

– **Specialized Industries**: Sportswear, advertising materials, and personalized gifts

### Regular Paper

– **Document Printing**: Reports, letters, and standard documents

– **Writing**: Note-taking, correspondence

– **Packaging**: Labels, wrappers (with appropriate weight)

– **Art and Crafts**: Drawing, painting, origami

– **Marketing Materials**: Flyers, brochures printed for direct distribution

## Cost and Availability

### Heat Transfer Paper

– **Higher Cost**: Significantly more expensive due to specialized coatings

– **Limited Availability**: Primarily sold at specialty stores or online

– **Specific Varieties**: Different types for different substrates (light/dark fabrics, hard surfaces)

– **Package Sizing**: Often sold in smaller quantities (10-100 sheets)

### Regular Paper

– **Economical**: Considerably less expensive

– **Widely Available**: Found in most stores, offices, and homes

– **Many Varieties**: Numerous options for weight, brightness, and finish

– **Bulk Availability**: Commonly sold in reams (500 sheets)

## Performance Considerations

### Heat Transfer Paper

– **Material Compatibility**: Works only with specific target materials

– **Temperature Sensitivity**: Requires precise heat control for optimal results

– **Storage Requirements**: Often needs controlled environment to prevent deterioration

– **Shelf Life**: May have limited usability period

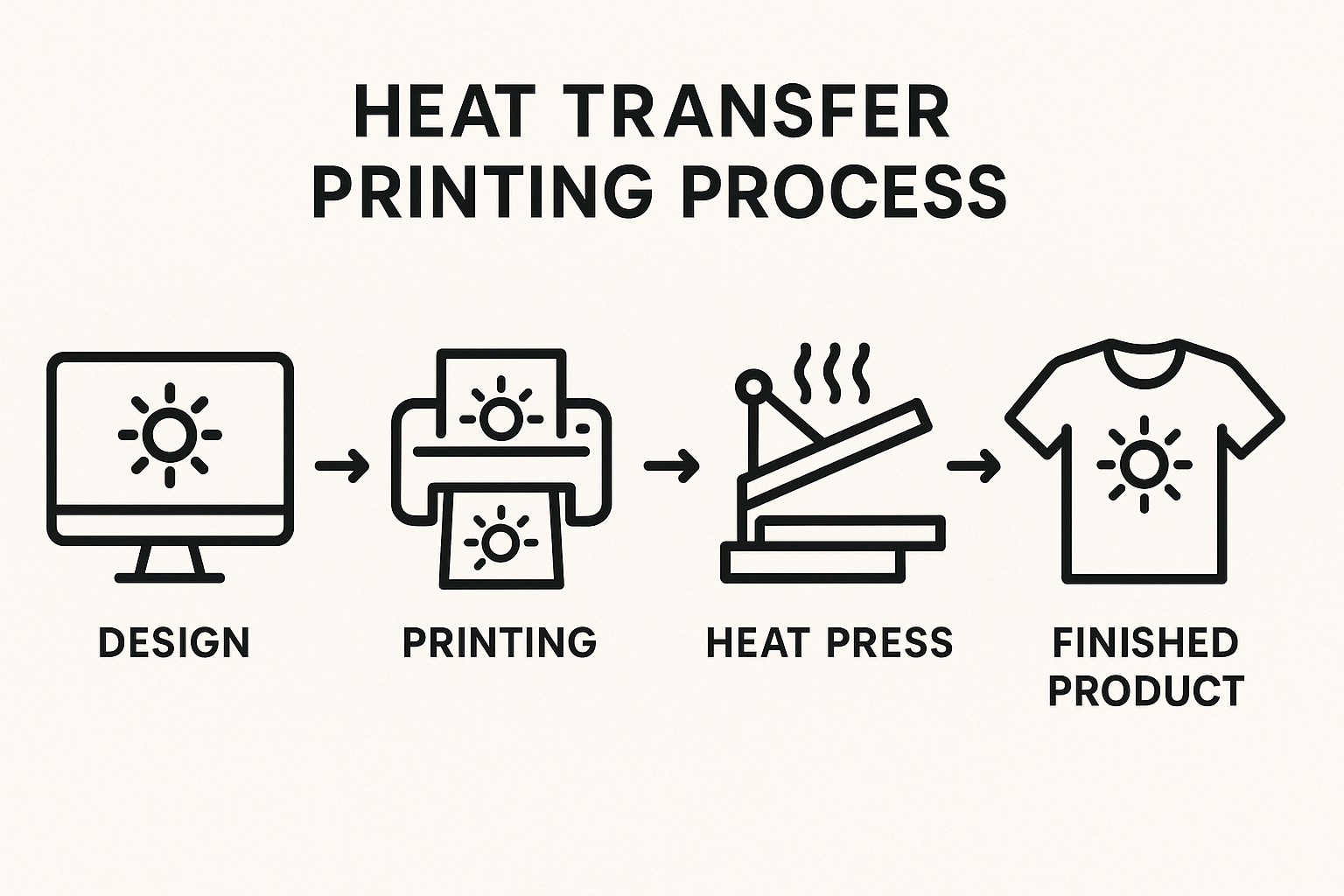

– **Application Process**: Requires additional equipment (heat press) and technical knowledge

### Regular Paper

– **Universal Compatibility**: Works with most standard printers and writing instruments

– **Temperature Tolerance**: Functions in wide environmental conditions

– **Simple Storage**: Requires only basic protection from moisture

– **Long Shelf Life**: Remains usable for years under proper conditions

– **Immediate Use**: Ready for direct application without additional processing

Understanding these differences is crucial for selecting the appropriate paper for specific projects and achieving desired results in printing and crafting applications.