What is Sublimation Printing and How Does it Work?

What is Sublimation Printing and How Does it Work?

Tired of designs that crack, peel, and fade over time? This makes your custom products look cheap and unprofessional, leading to unhappy customers and hurting your brand's reputation.

Sublimation printing uses special ink that turns into a gas under heat. This gas bonds permanently into the fibers of polyester fabrics or polymer-coated items, creating a vibrant, permanent design that has no feel and will not crack or fade.

When I took my first job in a sublimation factory, seeing the process up close felt like watching magic. A design on paper would disappear and reappear instantly on a shirt, perfectly embedded in the fabric. But it's not magic; it's science. And understanding this science is the single most important step to creating high-quality, professional products that people are willing to pay for. It's the knowledge that separates the hobbyists from the successful business owners. Let's break down exactly what you need and how it works.

What equipment do you actually need for sublimation?

Getting started in sublimation feels overwhelming. You see long lists of expensive gear, and buying the wrong equipment can waste thousands of dollars before you've even made your first product.

You only need four essential items: a sublimation printer with sublimation ink, sublimation paper, and a heat press. You will also need compatible "blanks"—items made of polyester or with a special polymer coating.

A common question I get from my clients is about the initial investment. My friend Alex, a product specialist in Canada, always advises them to start with the basics and master them. You don't need the most expensive industrial machine on day one. The core of your setup is the printer, often a converted inkjet like an Epson EcoTank, because their printheads work well with sublimation inks. The ink itself is the key ingredient—it’s not regular printer ink. This ink has the unique ability to turn from a solid (on the paper) to a gas when heated, bypassing the liquid stage. You print your mirrored design onto special sublimation paper, which is engineered to release up to 98% of the ink. Finally, a good heat press provides the two things needed for the magic to happen: high heat (around 180-200°C) and firm, even pressure. These four components work together to create the final product.

| Equipment | Function | Key Tip |

|---|---|---|

| Sublimation Printer | Prints your design using special ink. | An Epson EcoTank printer is a very popular and cost-effective choice for beginners. |

| Sublimation Ink | The unique dye that turns to gas. | Do NOT mix with regular ink. You dedicate one printer to sublimation only. |

| Sublimation Paper | A carrier sheet that holds and releases the ink. | Has a special coating. Don't confuse it with regular paper. |

| Heat Press | Provides the heat and pressure for transfer. | Invest in a quality press for even heat distribution to avoid ghosting or faded spots. |

What materials can you actually sublimate on?

You printed a beautiful design and pressed it onto a 100% cotton shirt. You feel great until it goes through the wash and the entire design disappears, wasting a shirt, ink, and paper.

Sublimation only works on man-made polymers. This means 100% polyester fabrics for the most vibrant results, or hard-surface items (called "blanks") that have a special polymer coating, like mugs, tiles, and metal panels.

The science here is simple but strict. The sublimation dye, in its gas form, can only bond with polyester molecules. It has nothing to latch onto with natural fibers like cotton or linen. This is why a design on a cotton shirt washes right out. When I advise my clients, I tell them to think in two categories: fabrics and hard goods. For fabrics, 100% white polyester will give you the most vibrant, photo-quality results. You can use poly-blends (like 50% polyester, 50% cotton), but the colors will look faded and have a "vintage" style because the ink only bonds to the polyester half of the fibers. This can be a great look if it's intentional! For hard goods, you can't just grab any mug from the store. You must buy items specifically sold as "sublimation blanks." These have been factory-treated with a clear coating of polymer, turning them into a printable surface. This opens up a huge world of products, from phone cases and keychains to ceramic tiles and photo-quality aluminum sheets.

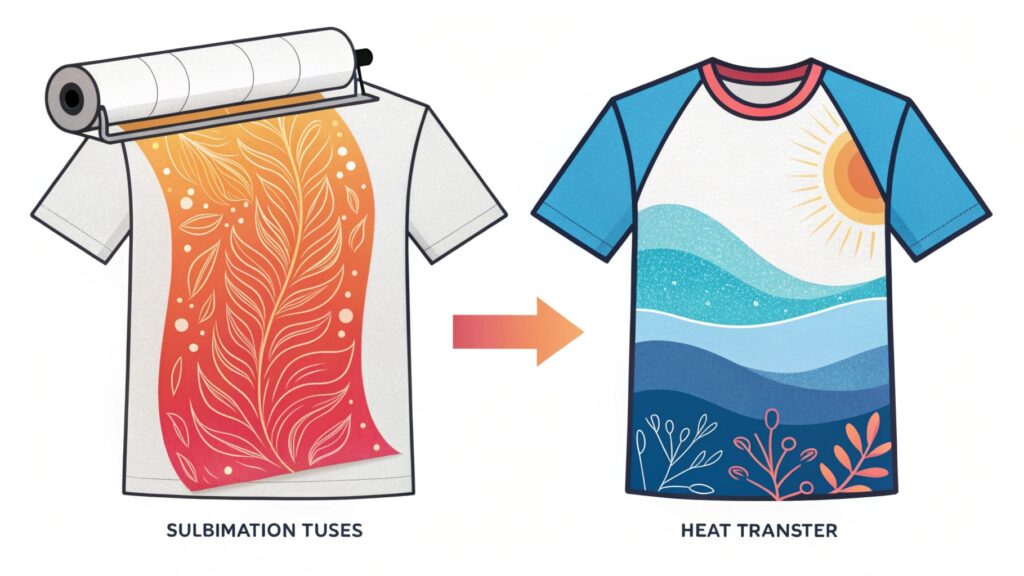

How is sublimation different from regular heat transfer?

People often use "sublimation" and "heat transfer" to mean the same thing, which is very confusing. Choosing the wrong method for a job can ruin the final product’s feel, durability, and overall quality.

They are opposite processes. Sublimation fuses ink into the fabric fibers, leaving no feel. Regular heat transfer applies a physical layer of vinyl or paper on top of the fabric, which you can feel with your hand.

I use a simple analogy with my clients: sublimation is a tattoo, and heat transfer is a high-tech sticker. A tattoo becomes part of the skin; a sticker sits on top. A sublimated design becomes part of the fabric itself. It has zero "hand" (the way a print feels) and is perfectly breathable because the fabric's fibers are just dyed, not covered. Because it's infused, it will never crack, peel, or fade. It's truly permanent. Heat transfer vinyl (HTV), on the other hand, is a sheet of material that is cut, placed on the shirt, and adhered to the surface with heat. You can feel its edge, and it sits on top of the weave. While professional HTV is very durable, it still has the potential to crack after many washes. Alex, my specialist friend, uses this distinction to guide his clients. He uses sublimation for high-performance sportswear and photo gifts. For bold logos on dark cotton T-shirts, heat transfer vinyl is the better tool for the job.

| Feature | Sublimation | Regular Heat Transfer (HTV) |

|---|---|---|

| Process | Ink becomes gas, fuses into fibers | Material layer adheres on top of fibers |

| Feel ("Hand") | Zero, cannot be felt | Noticeable, can feel the layer |

| Durability | Permanent, part of the fabric | Durable (50+ washes), but can eventually crack |

| Fabric | Polyester-only, light colors | Cotton, Poly, Blends, any color |

| Weeding | No weeding needed | Requires weeding away excess vinyl |

Conclusion

Sublimation creates permanent, vibrant designs by turning ink into gas. It requires specific gear and polyester materials, but it delivers unmatched quality for high-end, durable products.

Hi there! I'm Lucy, the guardian angel of two good children. During the day, I am a professional in the heat transfer printing industry, from factory workshops to running my own business. Here I share what I have learned - let's grow together!