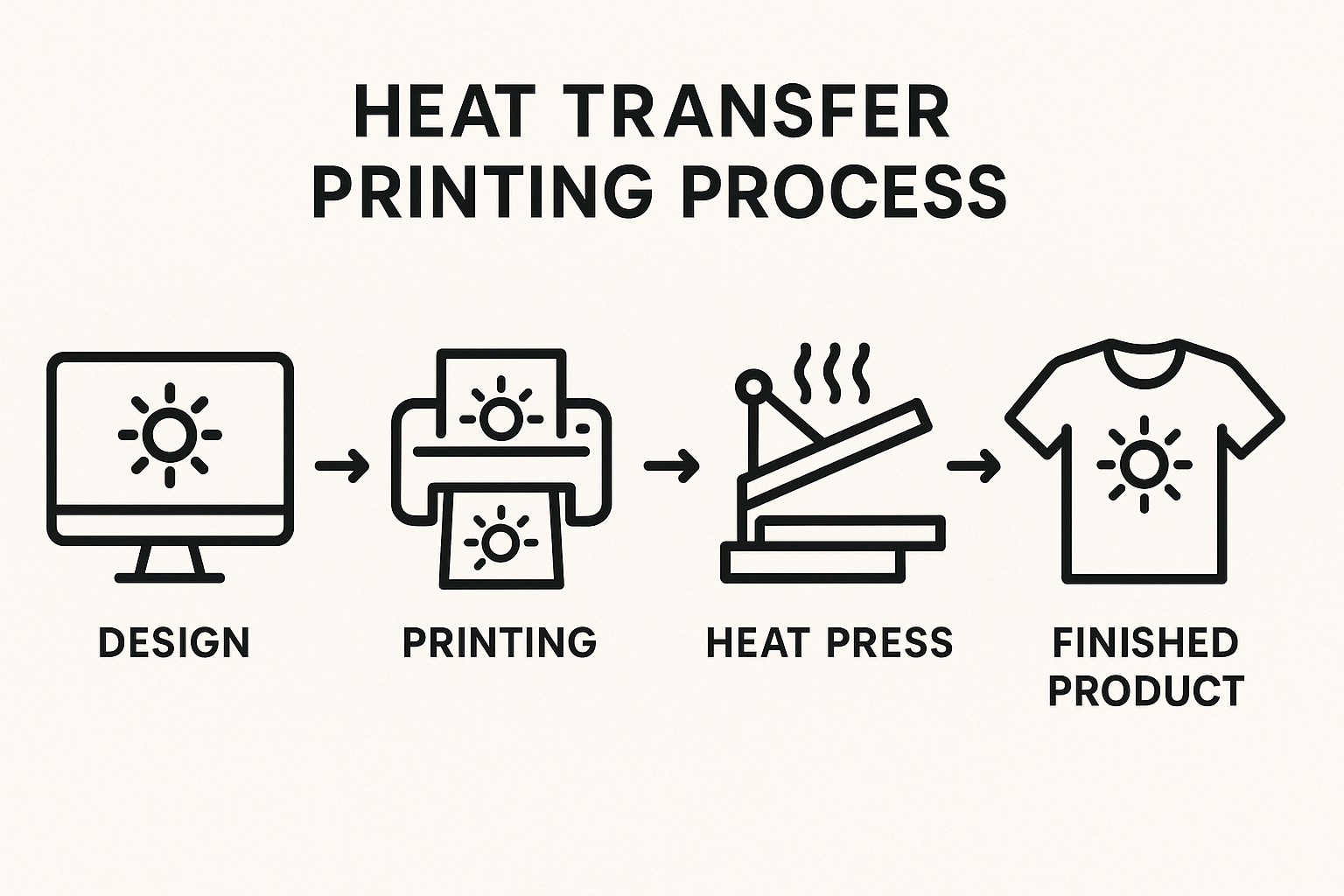

Important Considerations for Heat Transfer Printing

As a manufacturer of blank products for heat transfer printing, I’ve learned that achieving high-quality results requires attention to several critical factors. Whether you’re new to this printing method or looking to improve your existing process, here are the key considerations for successful heat transfer printing.

Understanding Your Substrate

The material you’re printing onto significantly impacts your results. Different substrates require specific temperature settings, pressure levels, and dwell times:

Polyester and polymer-coated items typically accept transfers well at 350-375°F (175-190°C)

Cotton blends might require 330-350°F (165-175°C)

Ceramics and metals often need higher temperatures and longer dwell times

Nylon and heat-sensitive materials demand lower temperatures and special transfer papers

Always test your specific material combinations before beginning production runs.

Transfer Paper Selection Matters

Not all transfer papers are created equal! Consider:

Light vs. dark substrate papers – these are formulated differently

Inkjet vs. laser printer compatibility

Cold or hot peel options – affecting your workflow timing

Specialty papers for unique materials like metals or ceramics

The right paper dramatically improves color vibrancy, durability, and overall print quality.

Heat Press Settings: The Trifecta

Successful heat transfer printing depends on three critical variables:

Temperature – Must be accurate and consistent across the entire press surface

Pressure – Too light fails to transfer; too heavy can damage substrates

Time – Typically 10-30 seconds, but varies significantly by material

Document your successful combinations for consistent results.

Pre-Press Preparation

Your workflow before pressing affects quality:

Ensure substrates are clean, dry, and lint-free

Pre-heat items for 5-10 seconds to remove moisture

Position transfers precisely with heat-resistant tape if needed

Consider using Teflon sheets to prevent scorching

Post-Press Handling

How you handle items after pressing impacts durability:

Follow proper peel techniques (hot vs. cold) based on your transfer paper

Allow items to cool completely before stacking or packaging

Provide proper care instructions to customers (typically waiting 24 hours before washing, washing inside-out, etc.)

Troubleshooting Common Issues

Even experienced printers encounter problems:

Incomplete transfers: Check temperature, pressure, and dwell time

Fading after washing: Consider pre-treatment solutions or higher-quality transfer papers

Scorching: Reduce temperature or use protective sheets

Ghosting or double images: Ensure stability during pressing

Conclusion

Heat transfer printing offers incredible versatility for customizing blank products, but success lies in understanding your materials, maintaining precise control of your equipment, and following proven processes. By giving attention to these critical factors, you’ll create transfers that maintain their vibrancy and durability through years of use.

What heat transfer printing challenges have you encountered? I’d love to hear your experiences in the comments below!